SUMITOMO- Poreflon PTFE – Submerge MBR Membrane

BLUFOX - MBR Membrane Manufacturer & Exporter Chat With UsGet QuoteFind the perfect MBR Membrane Manufacturer and Exporter

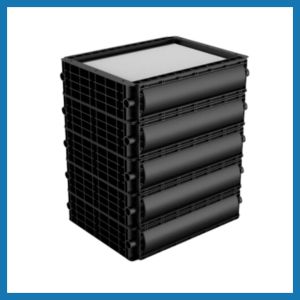

Submerge Type Poreflon Module

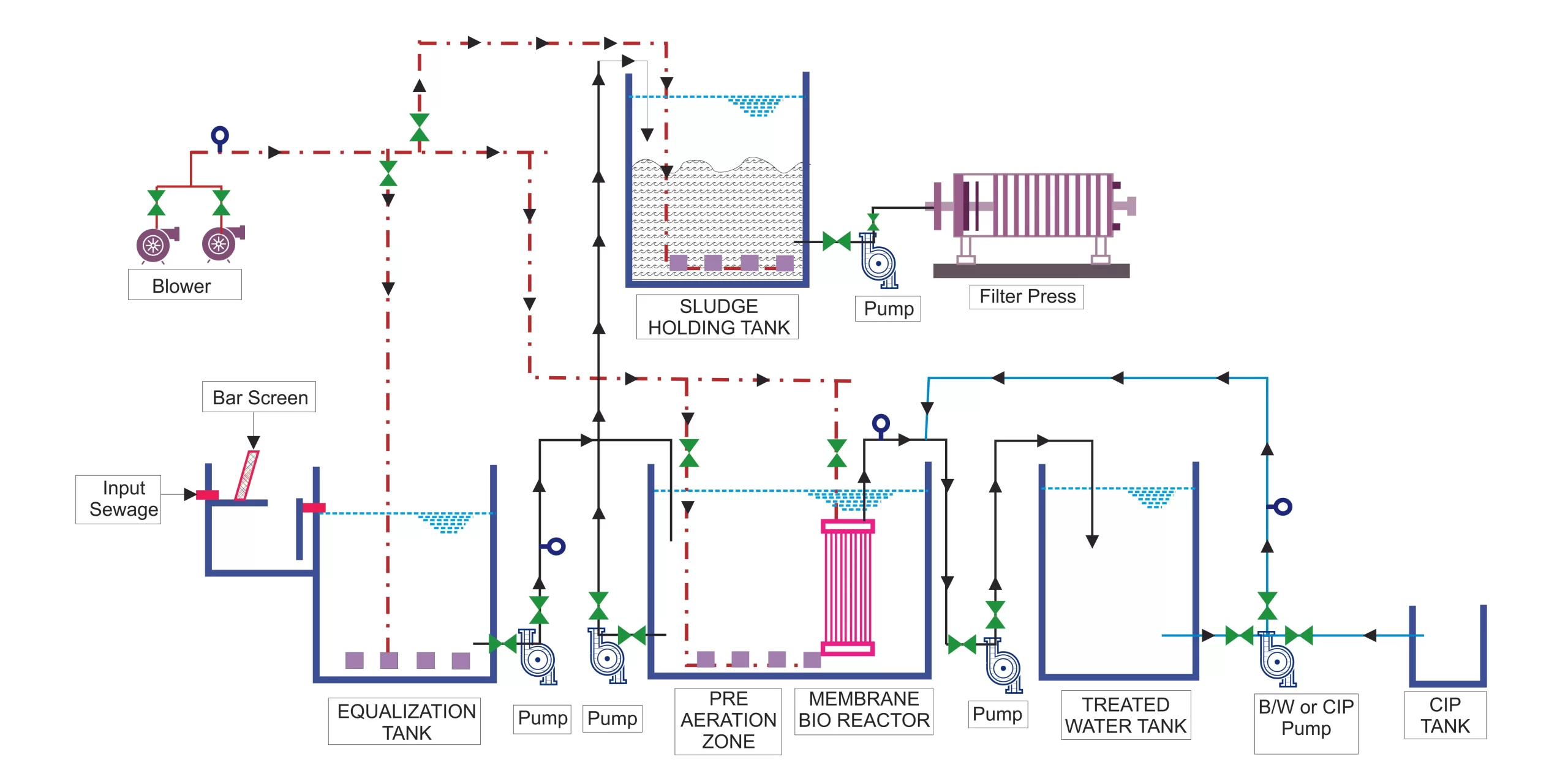

PTFE (Polytetrafluoroethylene) – Submerged MBR (Membrane Bioreactor) membranes are a specific type of membrane configuration used in wastewater treatment processes. PTFE is a synthetic fluoropolymer known for its excellent chemical resistance and low friction properties. Here’s an introduction to PTFE – Submerged MBR membranes, along with their working principles and advantages:

Introduction

PTFE – Submerged MBR membranes consist of membranes made from PTFE material. PTFE is widely used in various industries due to its exceptional chemical resistance, high temperature tolerance, and low fouling characteristics. In the context of MBR systems, PTFE membranes are submerged in the wastewater for the separation of solids, microorganisms, and contaminants.

Working

In a PTFE – Submerged MBR system, the membranes made from PTFE material are fully immersed in the wastewater. The wastewater is pumped or circulated over the membrane surfaces, creating a submerged filtration process. The membranes act as a selective barrier, allowing treated water or permeate to pass through while retaining suspended solids, bacteria, and other contaminants. The permeate is collected and further treated or discharged, while the retained solids and contaminants are periodically removed through backwashing or chemical cleaning to maintain the performance and permeability of the membranes.

Advantages of Submerge Type Poreflon Module

Excellent Chemical Resistance.

Low Fouling Characteristics.

High Temperature Tolerance.

Long Lifespan.

Versatility.

Easy Maintenance.

High-Quality Effluent.

Technical Details of SUMITOMO- Poreflon PTFE

| Model No. | SPMW | |||

| 12B6 | 12B12 | |||

| Membrane | Nominal pore size | um | 0.1 | 0.1 |

| Inner diameter | mm | 1.1 | 1.1 | |

| Outer diameter | mm | 2.3 | 2.2 | |

| Membrane area | m2 | 6 | 12 | |

| Material | PTFE | |||

| Hydrophilic treatment | Hydrophilic | |||

| Material | Cap | ABS resin (Joint nut : SUS303) | ||

| Potting | Heat- & chemical-resistant epoxy resin | |||

| Supporting bar | SUS304 | |||

| Dimensions | Length | mm | 1300 | 2410 |

| Bottom Section | mm | 154x164 | ||

| Operating Condition | Filtration method | Suction filtration | ||

| Trans membrane pressure | Filtration | >-60kPa | ||

| Backwash | <100kPa | |||

| Maximum temperature limit | 50 | |||

| Operating pH range | 0 - 14 | |||

| Cleaning pH range | 0 - 14 | |||

Example of Water Quality

| Example of water quality | ||

| Tolerance of row water quality | Tolerance of water | |

| CODcr | <10,000mg/L | <50mg/L |

| BOD | <5,000mg/L | <10mg/L |

| TSS | - | <1mg/L |

| Oil & Grease (Mineral Oil) | <50mg/L | <5mg/L |

| Oil & Grease (Animal & Vegetable Oil) | <300mg/L | <5mg/L |

Our Products

BF Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

SUS Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

Submerge Type Poreflon Module

POREFLON Membrane Modules are durable high – quality membranes that have a chemical and thermal resistance. These modules are reasonably priced and easy to handle.

Cross Flow Membrane

Cross Flow (Membrane Bioreactor) membranes are a type of filtration membrane configuration used in wastewater treatment processes.

SiC/Ceramic Membrane

SiC / Ceramic Membrane MBR (Membrane Bioreactor) membranes are a type of filtration membrane used in wastewater treatment processes.

Reverse Osmosis (RO) Membrane

Reverse Osmosis(RO) Membranes are a specialized type of membrane designed for high-efficiency water purification across wide range of applications.

Ultra Filtration (UF) Membrane

ZETA – Ultrafiltration membranes are designed for the separation of particles & micromolecules from liquids through a size based filtration process.

Happy Clients

I have been working with Blufox for 2 years now, and I am glad I chose them from the beginning. Their products are of very high quality, and my clients have never complained about their products. Besides MBR membranes, they also have other good quality products, such as water pumps and air blowers, which suit my projects well. So if possible, I suggest you try their other products as well.