Find the perfect MBR Membrane Manufacturer and Exporter

Sic/Ceramic Membrane

Ceramic MBR (Membrane Bioreactor) membranes are a type of filtration membrane used in wastewater treatment processes. They are made of ceramic materials such as alumina or zirconia and offer distinct advantages over polymeric membranes in certain applications. Here’s an introduction to ceramic MBR membranes, along with their working principles and advantages:

Introduction

Ceramic MBR membranes are characterized by their construction from inorganic ceramic materials. These materials provide exceptional mechanical strength, chemical resistance, and thermal stability. Ceramic membranes are commonly used in industrial wastewater treatment applications where there is a need for robust membranes capable of withstanding harsh operating conditions.

Working

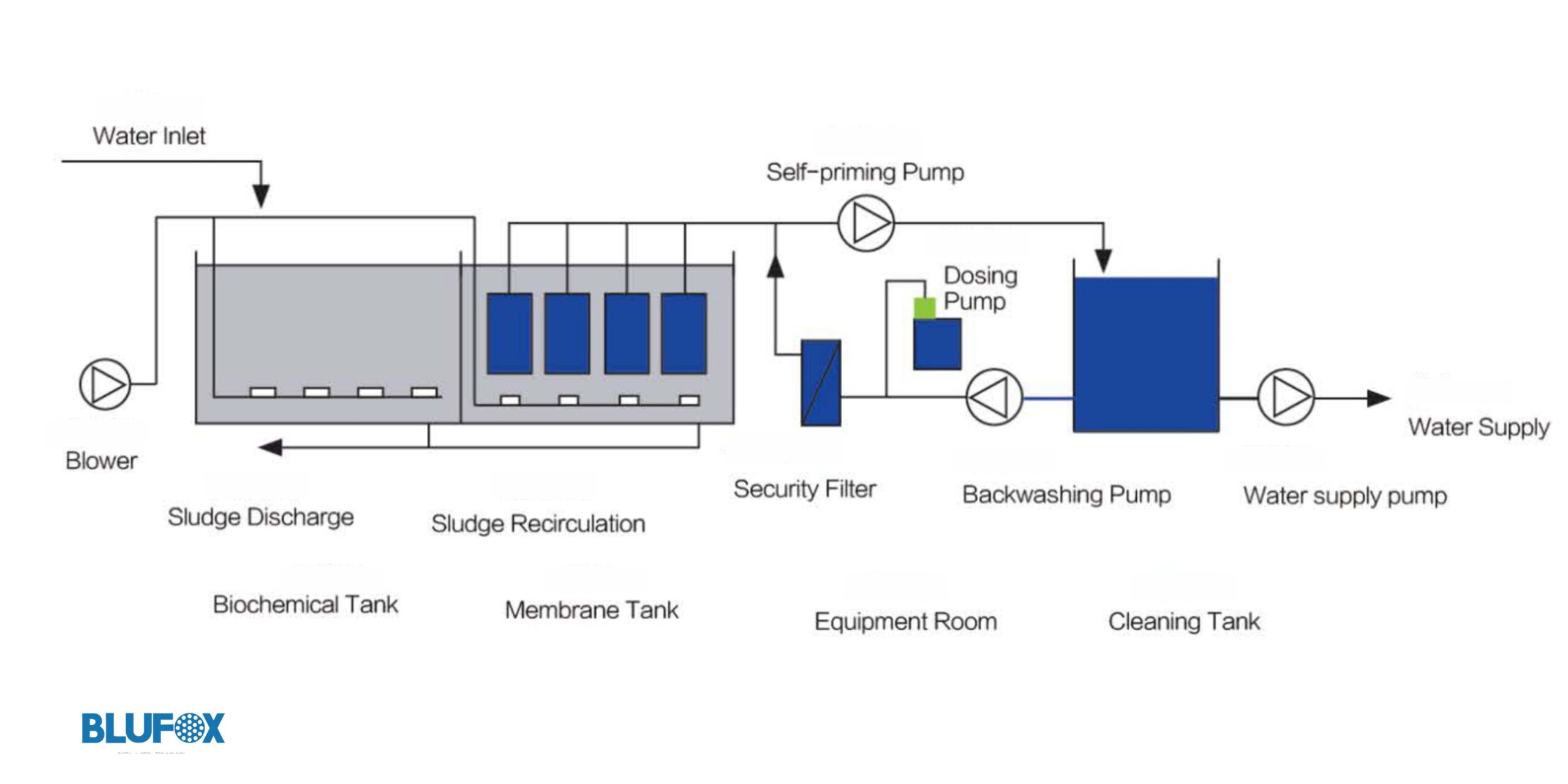

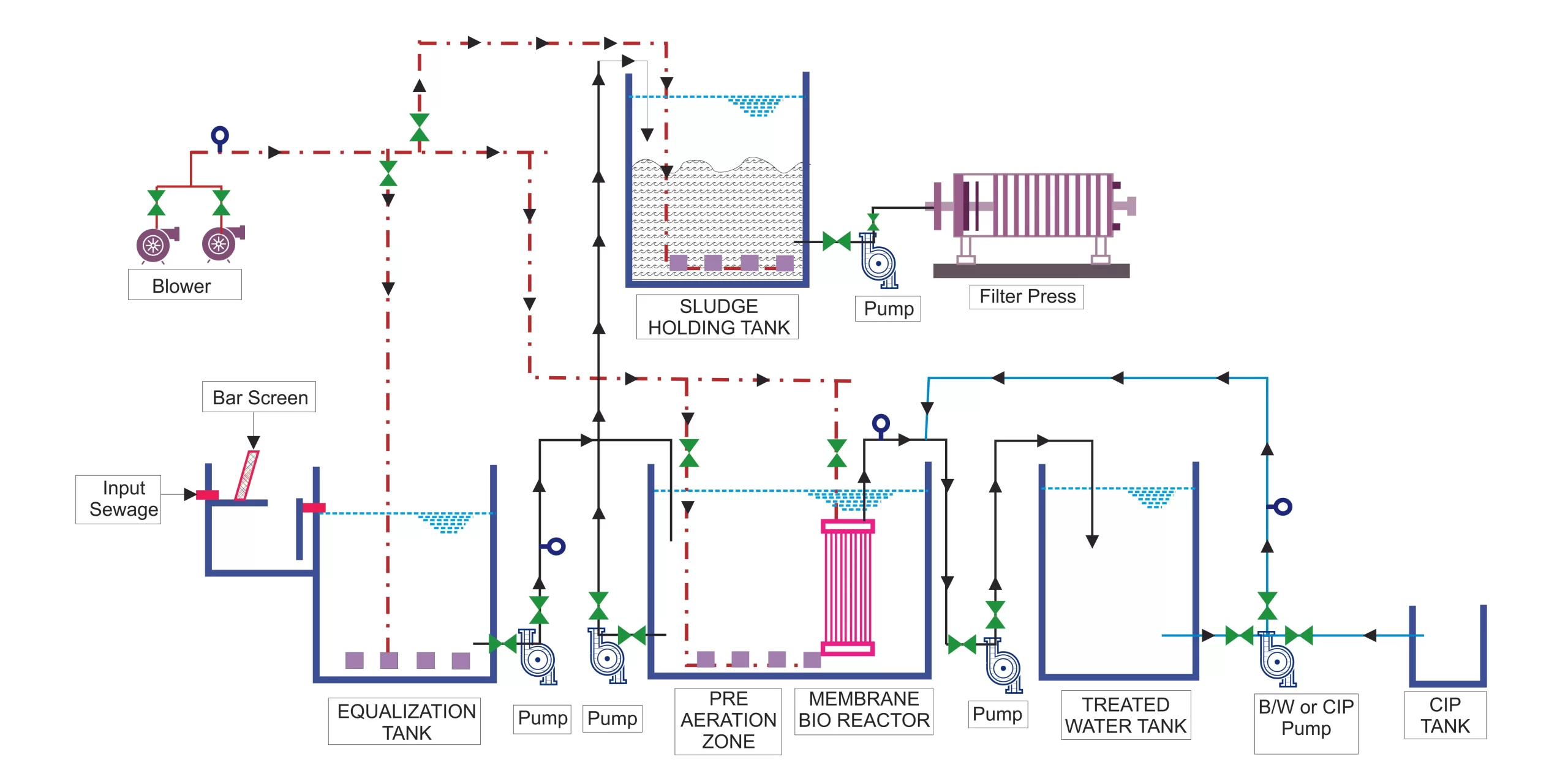

In a Ceramic MBR system, wastewater is introduced into the membrane module containing the ceramic membranes. The membranes act as a selective barrier, allowing water molecules to pass through while retaining suspended solids, bacteria, and other contaminants. Ceramic membranes typically have a dense structure with small, uniform pores, which contribute to their high filtration efficiency. The treated water or permeate is collected for reuse or discharge, while the retained solids and contaminants are removed from the membrane surface through periodic cleaning processes.

Advantages of Sic/Ceramic Membrane

Chemical and Thermal Stability.

Long Lifespan.

Wide pH Range Compatibility.

High Filtration Efficiency.

Sustainable Operation.

High Mechanical Strength.

Resistance to Fouling.

Enhanced Backwash Capability.

Reduced Chemical Consumption.

Ceramic MBR membranes offer unique advantages, including chemical and thermal stability, long lifespan, high mechanical strength, resistance to fouling, and excellent filtration efficiency. These qualities make them particularly suitable for industrial wastewater treatment applications where robust and reliable performance is required.

Principle

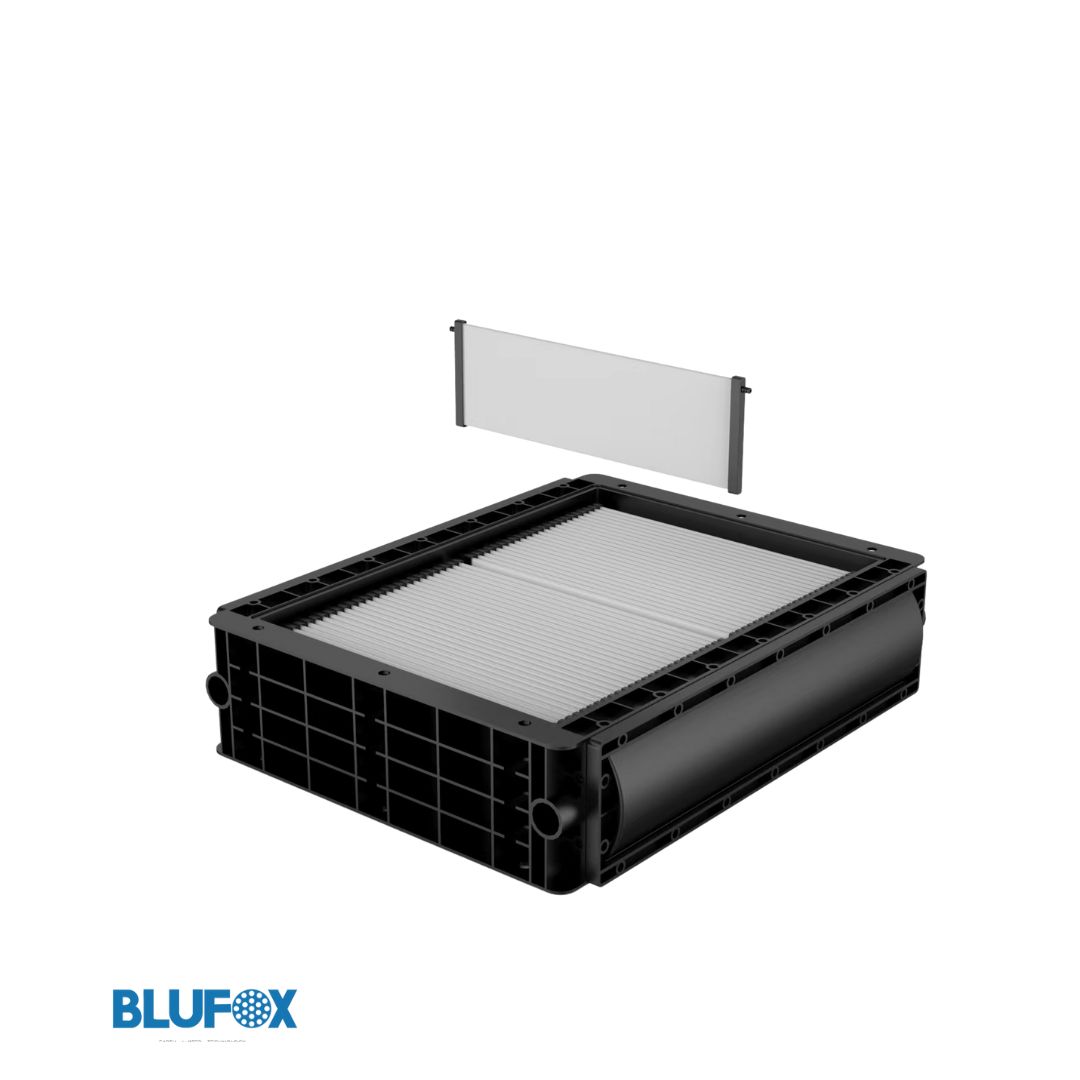

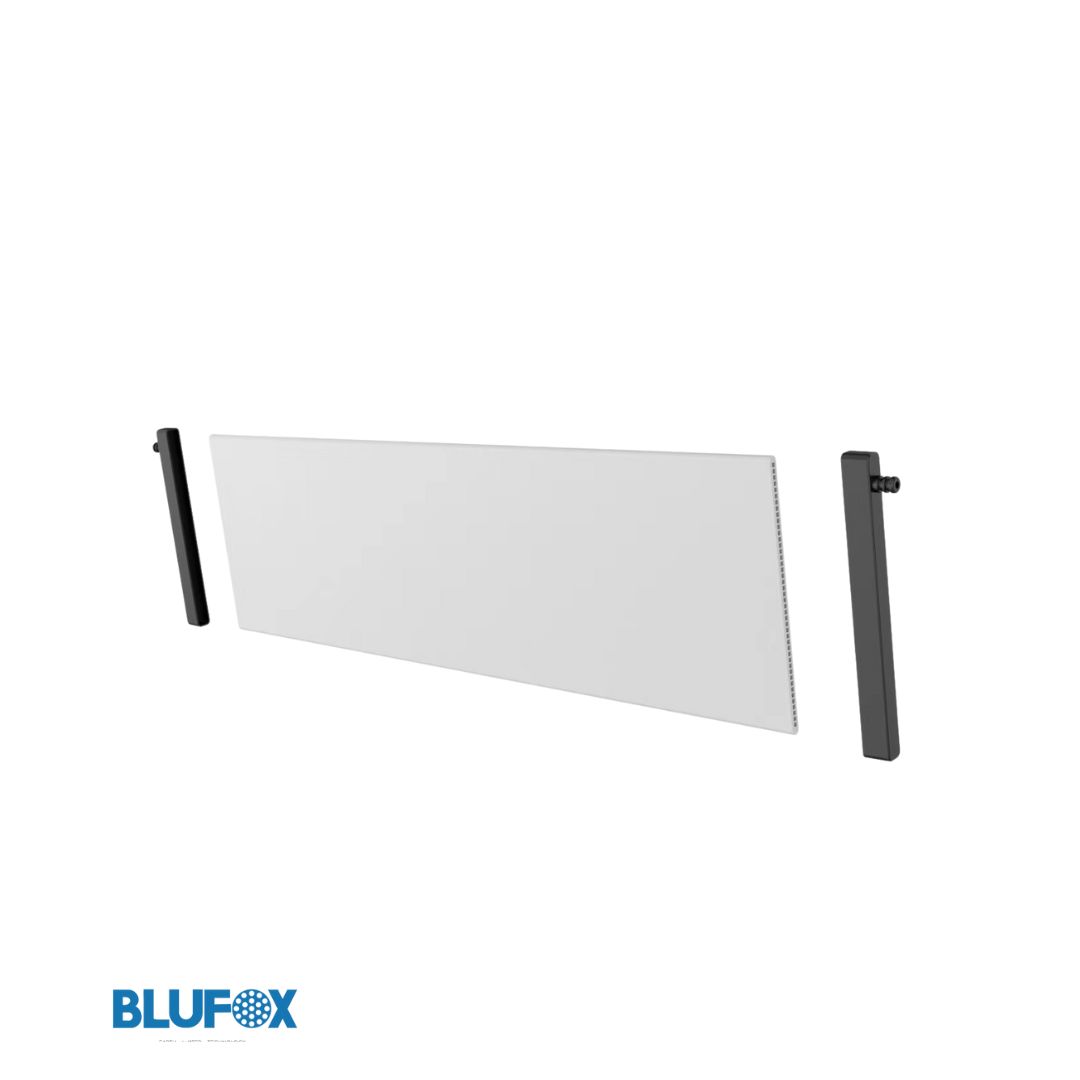

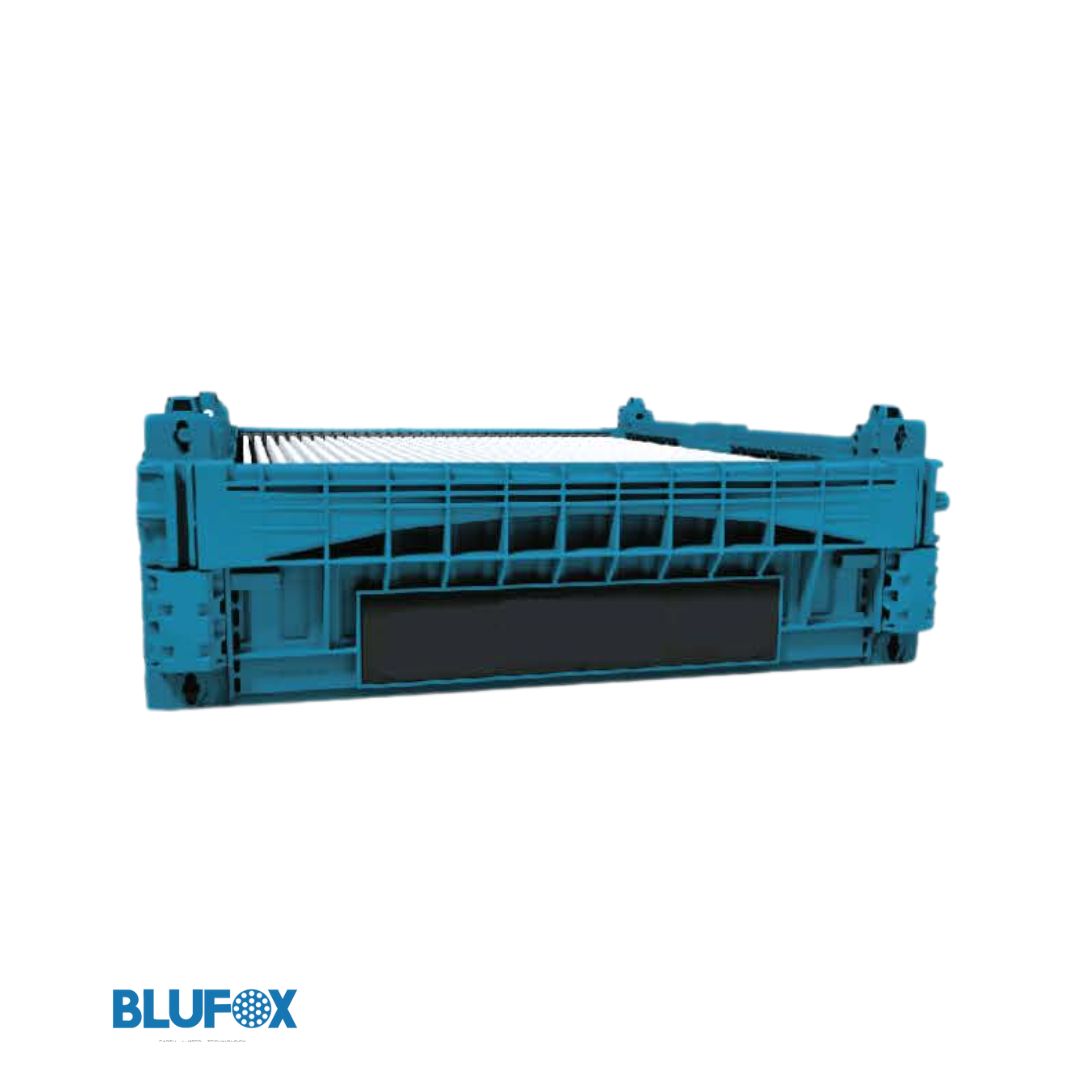

A flat sheet membrane is used in a submerged filtration system for material filtration separation or membrane bioreactor. The membrane is operated by immersion, with negative pressure suction, driving water flow through the membrane layer from the outside to the inside, and the tiny particles are blocked by the membrane layer to achieve the purpose of material separation. And after being blocked, the biochemical substance is attached to the surface of the membrane layer to form a biological filter cake layer, which realizes the function of the membrane bioreactor.

Sic/Ceramic Membrane Parameter

Technical Details of Sic/Ceramic Membrane

| Item | Specification | |||

| Membrane Material | Silicon Carbide | |||

| Size(mm) | L500*W130*H6 | L500*W160*H6 | L500*W200*H6 | L1000*W250*H6 |

| Membrane Area(m2) | 0.13 | 0.16 | 0.2 | 0.5 |

| Pore Size(um) | 0.1, 0.5, 1, 3, 5, 10 | |||

| Flux | 50-1200L/m2-h | |||

| pH | 0-14 | |||

| Maximum Pressure | -0.7 bar | |||

| Maximum Backwash Pressure | 3 bar | |||

| Operating Temperature | 5-80 °C | |||

| Cleaning Methods | Backwash/Air Wash/High Pressure Wash/Chemical Cleaning | |||

Process and Application of Sic/Ceramic Membrane Filtration

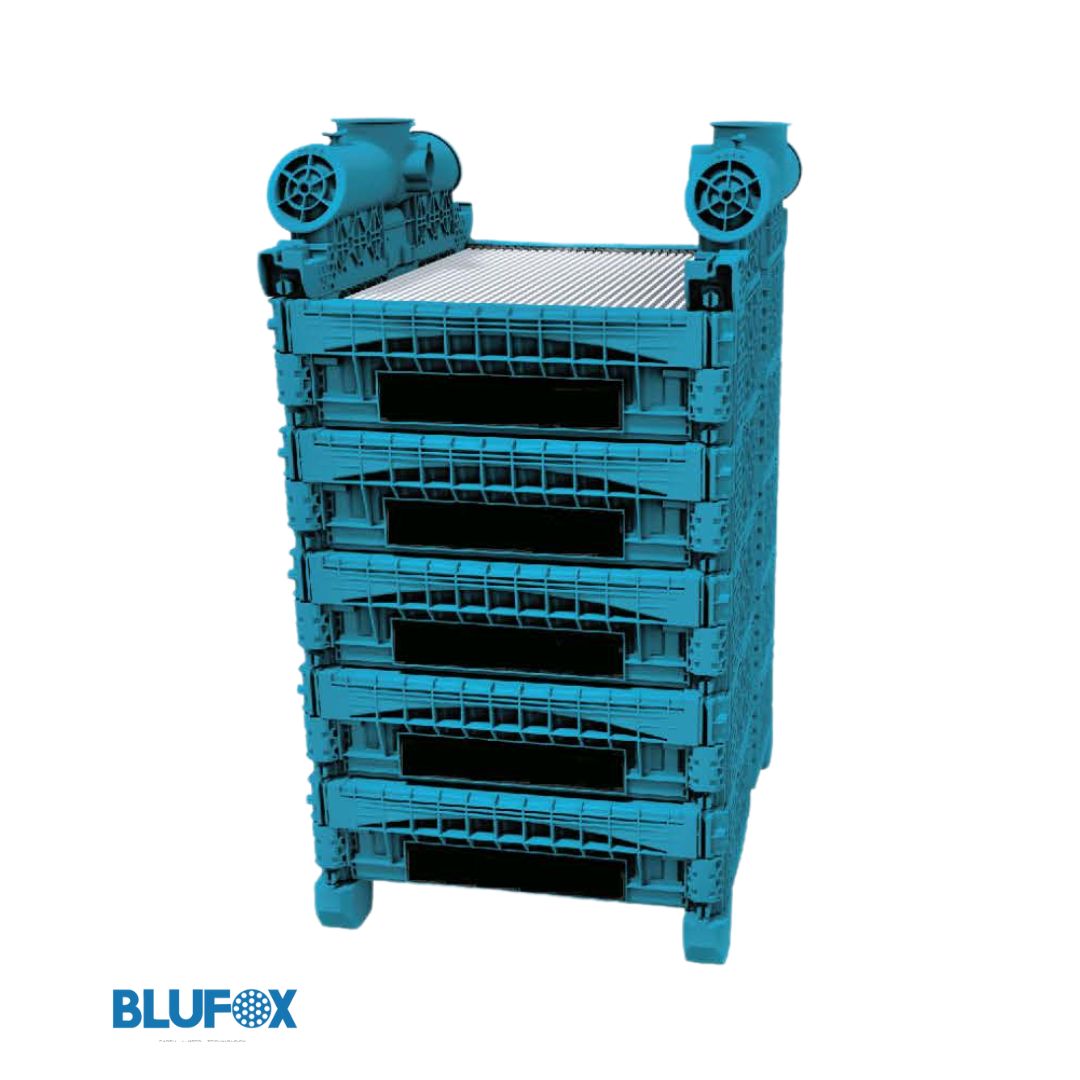

The module consists of several pieces of paralleled assembled SiC flat sheet membrane. Filtra- in the process is designed as submerged filtration. Modules are completely immersed in the membrane tank. Permeate water goes across the membrane by suction. It is collected to the product tank. The suspended solids are blocked.

Membrane Bio-Reactor(MBR)

SIC flat sheet membrane shows a variety of advantages as used in MBR, high flux, good chemical resistance, and high mechanical strength. It can be used in wastewater treatment for water reuse.

Product Parameter Table

| Type | mm | mm | mm | No. of single ceramic plates | m2 |

|---|---|---|---|---|---|

| B130 | 810 | 650 | 175 | 50 | 6.5 |

| B145 | 705 | 576 | 160 | 34 | 6 |

| B160 | 910 | 750 | 210 | 50 | 8 |

| B200 | 910 | 750 | 250 | 50 | 10 |

| B250 | 1800 | 1300 | 300 | 100 | 50 |

Happy Clients

I have been working with Blufox for 2 years now, and I am glad I chose them from the beginning. Their products are of very high quality, and my clients have never complained about their products. Besides MBR membranes, they also have other good quality products, such as water pumps and air blowers, which suit my projects well. So if possible, I suggest you try their other products as well.