SUS Series Hollow Fiber MBR Membrane

BLUFOX - MBR Membrane Manufacturer & Exporter Chat With UsGet QuoteFind the perfect MBR Membrane Manufacturer and Exporter

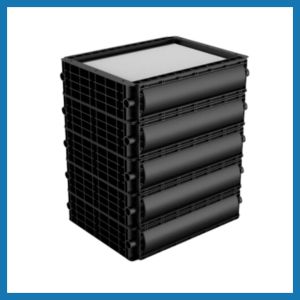

SUS Series Hollow Fiber MBR Membrane

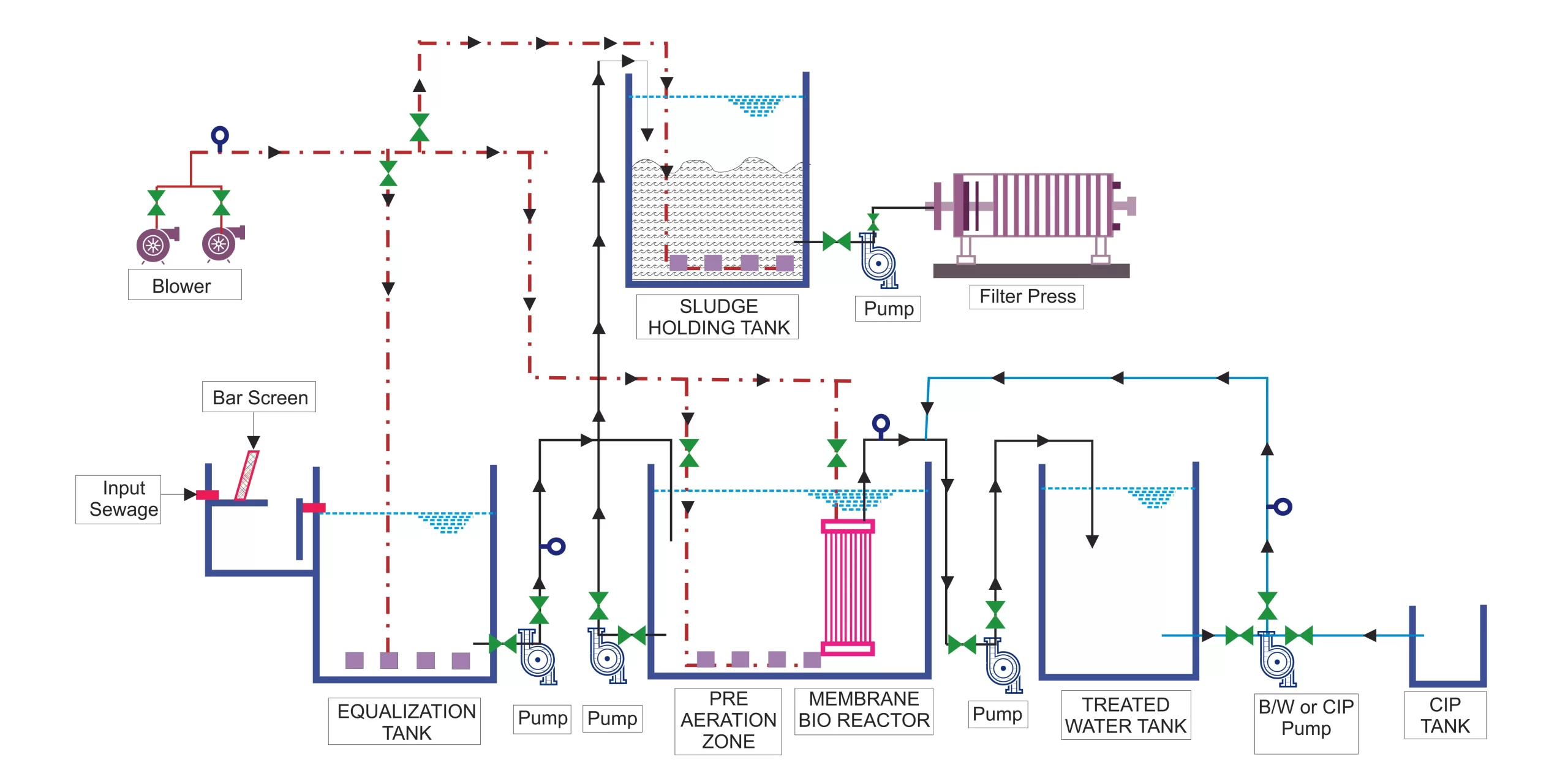

SUS Series MBR membranes are a specific type of membrane configuration used in Membrane Bioreactor (MBR) systems for wastewater treatment. These membranes are characterized by their unique structure and design, which offer distinct advantages in terms of filtration efficiency and system performance.

Introduction

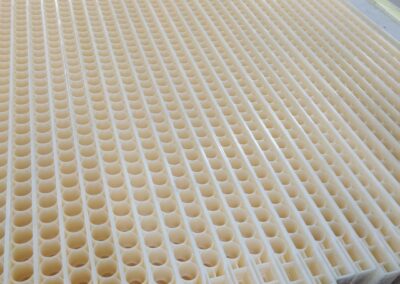

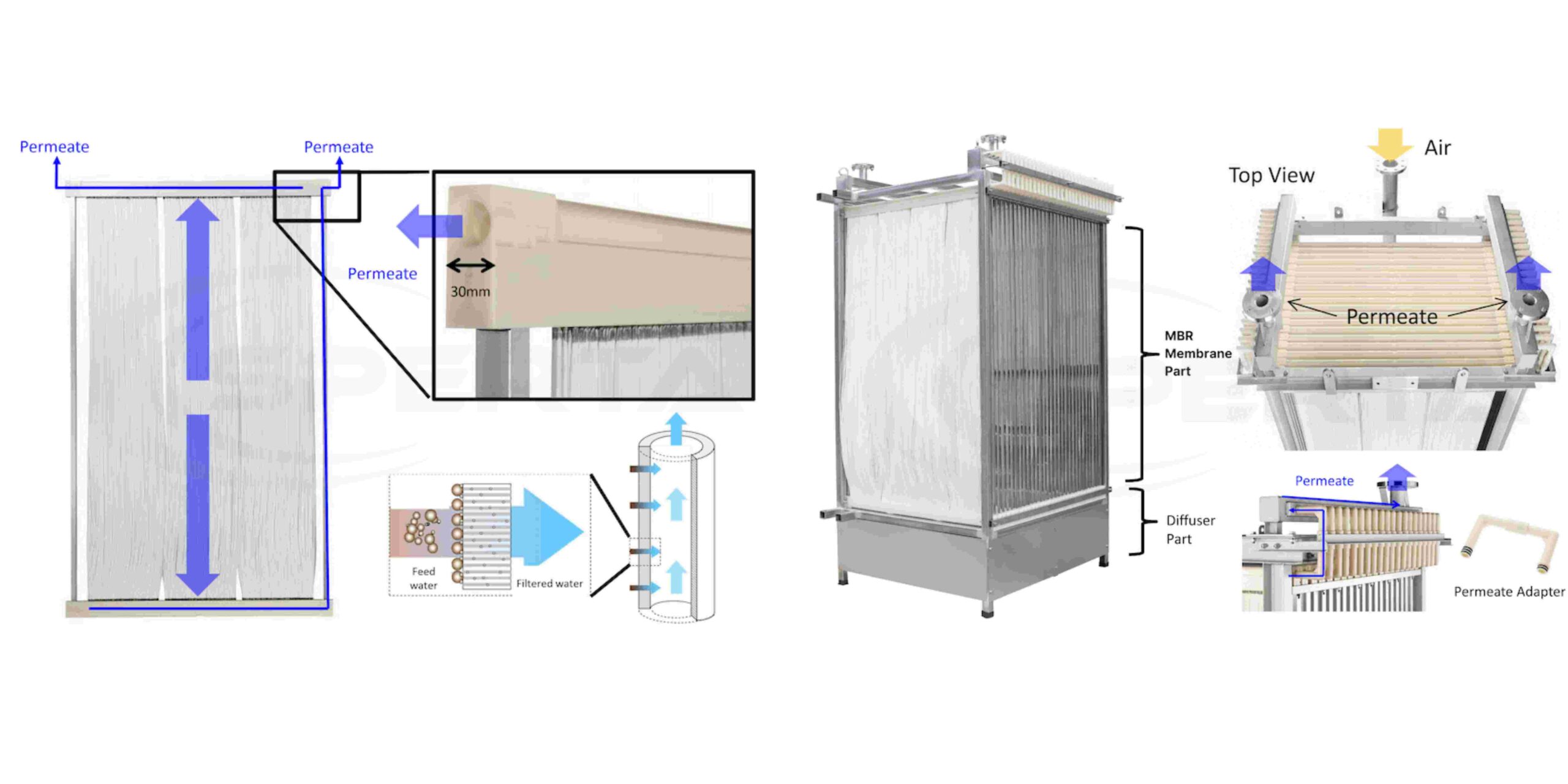

SUS Series MBR membranes consist of numerous hollow fibers bundled together to form a module. These hollow fibers are made of materials such as polyethylene, polypropylene, or polysulfone and have a cylindrical shape with a porous inner core and a dense outer skin. The membranes are arranged in a parallel or closely packed configuration within the module.

Working

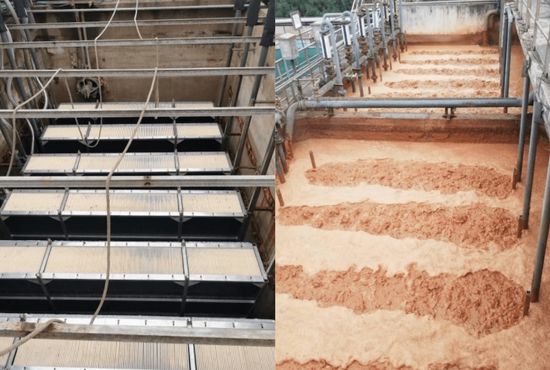

SUS Series MBR systems, wastewater is introduced into the membrane module, and the hollow fibres act as a physical barrier. The porous inner core of the hollow fibers allows water to pass through, while suspended solids, bacteria, and other contaminants are retained on the outer surface or trapped within the fibre structure. The treated water permeates through the hollow fibers and is collected as the filtrate.

Key Features of SUS Series MBR Membranes

Advantages of SUS Series MBR Membrane

High Filtration Efficiency

Enhanced Solid-Liquid Separation.

Reduced Fouling and Clogging.

Compact System Design.

Higher Flux Rates.

Robust and Durable.

Versatile Application.

Fibres with excellent quality reinforced PVDF

High Strength PET/ Epoxy Potting

Less backwash water and less air required

Hydrophilized membrane surface for ease of handling & maintenance

SUS Series Hollow Fiber MBR Membrane Working Principle

| Model | SUS120 | SUS140 | SUS238 | SUS250 | SUS350 |

|---|---|---|---|---|---|

| Membrane Size (sq.mtr.) | 12 | 14 | 23.8 | 25 | 35 |

| Flow (LPD) @ 15LMH | 3600 | 4200 | 7140 | 7500 | 10500 |

| Membrane Material | R - PVDF (PET Layer Support) | ||||

| Membrane Type | Outside - to - Inside | ||||

| O/I dia (Fiber size) | 2.5/1.2 mm | ||||

| Pore size | 0.03 - 0.2 µm | ||||

| Permeate flux | 10-40 LMH | ||||

| Operating pressure | (-2.95 to -17.71 inHg) | ||||

| Operating Temp. | 10-40° C | ||||

| Element Dimension | 1300x680x30 | 1500x680x30 | 1300x1250x30 | 1500x1250x30 | 2000x1250x30 |

| B/W flux | 15-60 LMH | ||||

| Turbidity Inlet | <100-200 NTU | ||||

| Turbidity Outlet | <3-1 NTU | ||||

| NaClO Tolerance | 5000 ppm | ||||

| Element Water Collecting Header | ABS resin | ||||

| CIP Process | Offline/Online | ||||

Applications of SUS Series Hollow Fiber MBR Membrane

Municipal Wastewater Treatment

Expressway Wastewater Treatment

Hospital Wastewater Treatment

Husbandry Wastewater Treatment

Chemical Wastewater Treatment

Hospital Wastewater Treatment

Our Products

BF Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

SUS Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

Submerge Type Poreflon Module

POREFLON Membrane Modules are durable high – quality membranes that have a chemical and thermal resistance. These modules are reasonably priced and easy to handle.

Cross Flow Membrane

Cross Flow (Membrane Bioreactor) membranes are a type of filtration membrane configuration used in wastewater treatment processes.

SiC/Ceramic Membrane

SiC / Ceramic Membrane MBR (Membrane Bioreactor) membranes are a type of filtration membrane used in wastewater treatment processes.

Reverse Osmosis (RO) Membrane

Reverse Osmosis(RO) Membranes are a specialized type of membrane designed for high-efficiency water purification across wide range of applications.

Ultra Filtration (UF) Membrane

ZETA – Ultrafiltration membranes are designed for the separation of particles & micromolecules from liquids through a size based filtration process.

Happy Clients

I have been working with Blufox for 2 years now, and I am glad I chose them from the beginning. Their products are of very high quality, and my clients have never complained about their products. Besides MBR membranes, they also have other good quality products, such as water pumps and air blowers, which suit my projects well. So if possible, I suggest you try their other products as well.