Find the perfect MBR Membrane Manufacturer and Exporter

Cross Flow – Non Submerge MBR Membrane

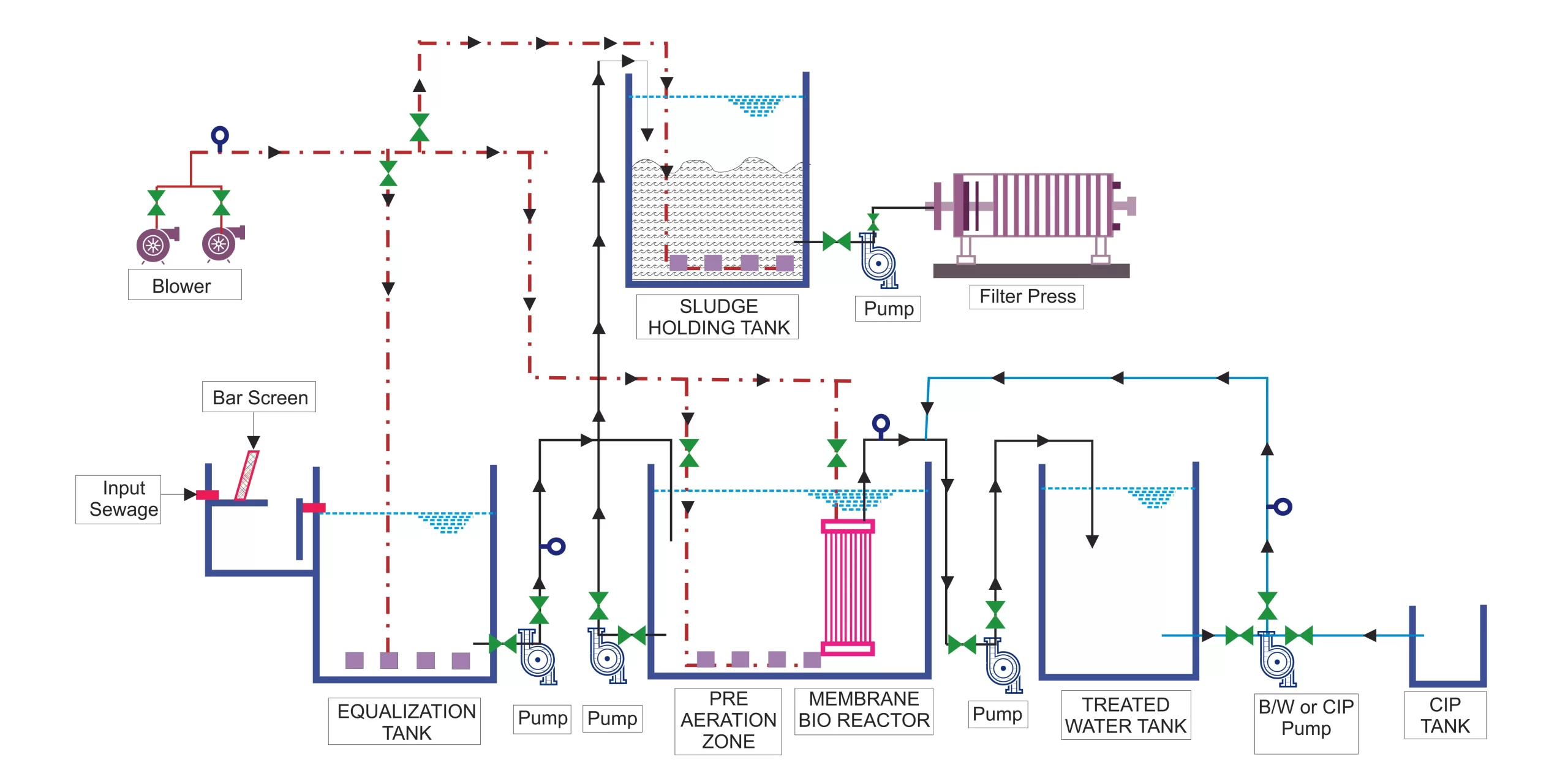

Cross Flow – Non Submerge MBR (Membrane Bioreactor) membranes are a type of filtration membrane configuration used in wastewater treatment processes. Unlike submerged MBR systems where the membranes are fully submerged in the wastewater, cross flow non-submerged systems utilize a partial submersion or non-submersion approach. Here’s an introduction to cross flow – non-submerged MBR membranes, along with their working principles and advantages:

Introduction

Cross Flow – Non Submerge MBR membranes are designed to operate with a partial submersion or non-submersion configuration. This configuration allows for a controlled flow of wastewater across the membrane surface, facilitating the separation of solids, microorganisms, and contaminants from the treated water.

Working

In a Cross Flow MBR Membrane system, the wastewater flows tangentially across the membrane surface, creating a cross flow filtration mode. The membranes, which are typically flat sheet or hollow fiber configurations, act as a physical barrier. As the wastewater passes over the membrane surface, suspended solids, bacteria, and other contaminants are retained while the treated water or permeate flows across the membrane and is collected for further use or discharge.

To maintain the efficiency of the process and prevent fouling, the system relies on periodic backwashing or air scouring to remove accumulated solids from the membrane surface. The backwash or air scouring action helps to minimize fouling, maintain permeability, and ensure continuous filtration performance.

Benefits of Tubular UF Membrane Modules

Unlike outside-in filtration, as seen with submerged membrane technology, our robust tubular UF (ultrafiltration) membranes enable operators to sustain higher flux rates with less frequent cleanings and reduced maintenance. In addition you get:

Higher flux and output

High quality permeate ideal as pretreated feed for RO systems

Fouling-resistant membranes due to crossflow filtration

Less frequent cleaning resulting in reduced chemical costs

Decrease in system downtime

More robust membranes that are less susceptible to breakage

The best ultrafiltration membrane filter

Ultrafiltration Membrane Filters Specification

5 mm Membrane Modules

The 5 mm inner diameter of the tubular membrane modules from Blufox Membranes are excellent in treating low-strength wastewater and effluent

streams that contains a low amount of solids.

8 mm Membrane Modules

The 8 mm inner diameter of our high-solids tubular membranes makes them ideally suited for high-strength wastewater treatment and effluent

streams while maintaining superior fouling resistance.

CR Membrane Modules

The superior robustness of Blufox’s CR membranes enable them to exhibit impressive resistance to a wide variety of chemicals and pH values (2–12), making them ideal for applications with high- trength influent.

UF Module Replacement

With over Many years of experience within the membrane industry, our engineers can fully support you in creating an optimum plan for the replacement of your

tubular Ultrafiltration membrane modules.

Advantages of Cross Flow – Non Submerge MBR membrane

Improved Filtration Efficiency.

Flexible System Design: Cross Flow.

Enhanced Process Control.

Water Reuse Potential.

Reduced Fouling and Maintenance.

Scalability.

Suitable for Challenging Wastewaters.

Cross Flow – Tubular UF Membranes Technical Specifications

| Model | MO 63 I8V | MO 84G_I8 XL V | MO 104G_I8 XL V |

|---|---|---|---|

| Dia | 156 | 210 | 260 |

| Length (mm) | 3000 | 4000 | 4000 |

| Membrane Area (m2) | 15.2 | 36.7 | 53.4 |

| Housing Material | FRP | FRP | FRP |

| Membrane Material | PVDF | PVDF | PVDF |

| Filter Type | Cross Flow | Cross Flow | Cross Flow |

| Pore Size (μm) | 0.03 | 0.03 | 0.03 |

| Fiber OD (mm) | 8 | 8 | 8 |

| Permeate Turbidity (NTU) | ≤ 1 | ≤ 1 | ≤ 1 |

| Permeate SDI | ≤ 3 | ≤ 3 | ≤ 3 |

| Temperature Range(℃) | 5-60 | 5-60 | 5-60 |

| pH Range | 2-10 | 2-10 | 2-10 |

| Designed Flow (L/m2/hr) | 40-120 | 40-120 | 40-120 |

| Max. TMP (KPa) | -20 to +800 | -80 to +1000 | -20 to +800 |

| Max. Feed Circulation | 36m3/hr. | 66m3/hr. | 96.1m3/hr. |

Industries We Serve

Dairy

Oil & Gas

Textile & Tannery

Mining & Metals

Food & Beverage

Chemical & Petrochemical

Landfill Leachate

Our Products

BF Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

SUS Series Hollow Fiber MBR Membrane

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

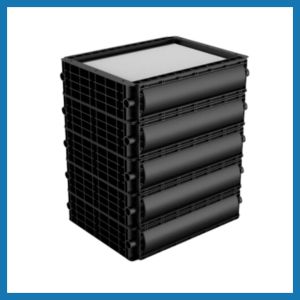

Submerge Type Poreflon Module

POREFLON Membrane Modules are durable high – quality membranes that have a chemical and thermal resistance. These modules are reasonably priced and easy to handle.

Cross Flow Membrane

Cross Flow (Membrane Bioreactor) membranes are a type of filtration membrane configuration used in wastewater treatment processes.

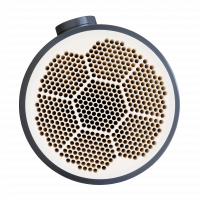

SiC/Ceramic Membrane

SiC / Ceramic Membrane MBR (Membrane Bioreactor) membranes are a type of filtration membrane used in wastewater treatment processes.

Reverse Osmosis (RO) Membrane

Reverse Osmosis(RO) Membranes are a specialized type of membrane designed for high-efficiency water purification across wide range of applications.

Ultra Filtration (UF) Membrane

ZETA – Ultrafiltration membranes are designed for the separation of particles & micromolecules from liquids through a size based filtration process.

Happy Clients

I have been working with Blufox for 2 years now, and I am glad I chose them from the beginning. Their products are of very high quality, and my clients have never complained about their products. Besides MBR membranes, they also have other good quality products, such as water pumps and air blowers, which suit my projects well. So if possible, I suggest you try their other products as well.