Find the perfect MBR Membrane Manufacturer and Exporter

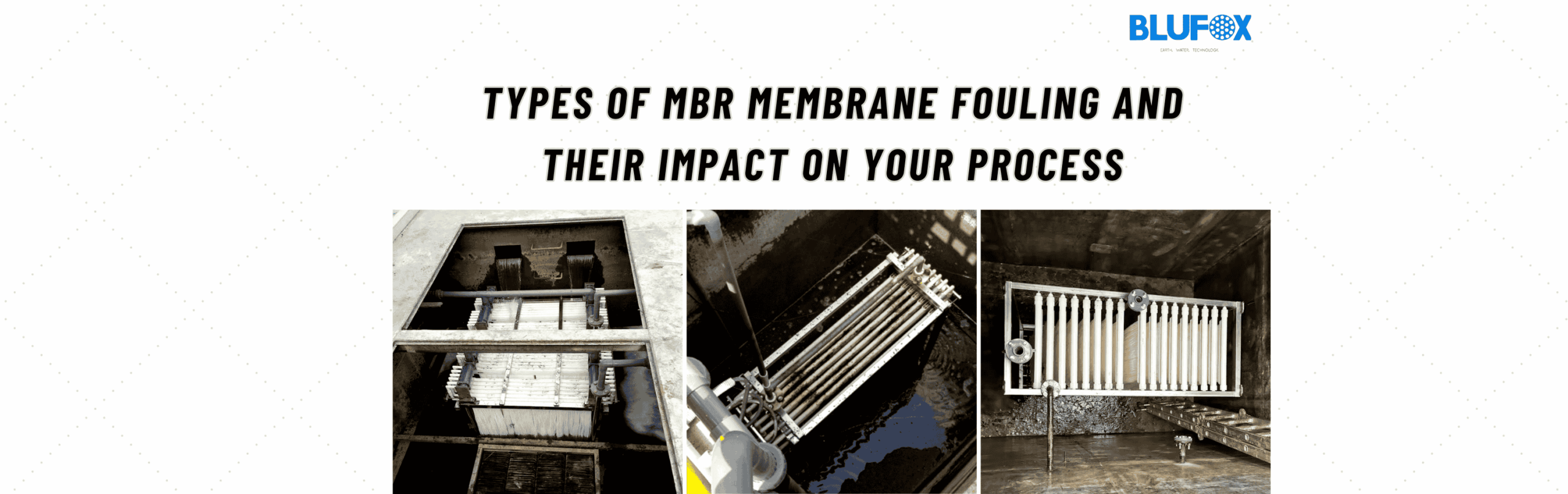

Types of MBR Membrane Fouling and Their Impact on Your Process

Membrane Bioreactor (MBR) membranes are highly effective for wastewater treatment, but they are prone to fouling, which can reduce efficiency. Here are the main types of fouling and how they affect your system:

1. Organic Fouling

Occurs when organic materials (fats, oils, proteins) accumulate on the membrane.

-

- Impact: Reduces permeability, increases transmembrane pressure (TMP), and requires frequent cleaning.

- Prevention: Regular cleaning and pre-treatment to reduce organic load.

2. Inorganic Fouling (Scaling)

Caused by the precipitation of minerals like calcium and magnesium, forming hard deposits.

-

- Impact: Increases TMP, energy consumption, and can cause permanent membrane damage.

- Prevention: Adjust pH and perform regular acid cleaning.

3. Biological Fouling (Biofouling)

Microorganisms form biofilms on the membrane surface.

-

- Impact: Biofilms resist cleaning, reduce filtration efficiency, and accelerate membrane wear.

- Prevention: Regular chemical cleaning with disinfectants like sodium hypochlorite.

4. Colloidal Fouling

Occurs when fine particles, such as silt or colloids, block the membrane pores.

-

- Impact: Causes flux decline, increases energy use, and is difficult to clean.

- Prevention: Pre-treat water and conduct routine backwashing.

What Exactly is Organic Fouling?

Organic fouling is a common and challenging issue in membrane-based water treatment systems. It occurs when organic compounds—such as proteins, oils, fats, and carbohydrates—accumulate and adhere to the surface of a membrane. These substances form a sticky, gelatinous layer that clogs the pores of the membrane, significantly reducing its efficiency and lifespan.

In the case of organic fouling, the membrane’s ability to filter water is compromised because the fouling layer acts as a physical barrier. This sticky layer prevents water from passing through freely, leading to increased pressure requirements, reduced permeate flow, and higher operational costs.

One of the key reasons organic fouling is so problematic is that it not only blocks the membrane but can also promote microbial growth. Over time, this can lead to biofouling, a more complex form of membrane contamination that combines both biological and organic fouling.

To control organic fouling, it’s essential to implement proper pretreatment processes, regular membrane cleaning schedules, and advanced membrane technologies like those provided by BLUFOX membranes. Our PVDF hollow fiber membranes are specially designed to resist organic fouling, ensuring better performance, longer service life, and reduced maintenance.

Understanding and managing organic fouling is critical for the success of any MBR, UF, STP, or ETP system. At BLUFOX, we’re committed to delivering high-performance membrane solutions that minimize fouling risks and maximize operational efficiency.

How Does Inorganic Fouling Differ from Organic Fouling?

Inorganic fouling, also known as scaling, occurs when dissolved minerals in water—such as calcium, magnesium, silicates, or sulfates—precipitate and deposit on the surface of a membrane. Unlike organic fouling, which is caused by sticky substances like fats and proteins, inorganic fouling results from chemical imbalances in the water that lead to crystal formation and hard deposits on the membrane surface.

This type of fouling can significantly impact membrane performance by clogging pores, reducing permeability, and increasing the pressure required to maintain water flow. Over time, inorganic fouling not only lowers system efficiency but also raises operational costs due to the need for frequent cleaning or membrane replacement. At BLUFOX membranes, we focus on advanced solutions to help minimize both organic and inorganic fouling, ensuring reliable and long-lasting membrane performance.

Why Should We Worry About Colloidal Fouling?

Colloidal fouling is a serious concern in membrane-based filtration systems because it involves the accumulation of fine, suspended particles—such as clay, iron, aluminum, or organic matter—on the membrane surface. These particles are so small that they don’t settle easily and can easily pass through pretreatment stages if not properly managed. When they stick to the membrane, they form a dense layer that disrupts water flow and clogs membrane pores.

This type of fouling reduces membrane efficiency, increases pressure drop, and shortens membrane lifespan, leading to higher energy consumption and operational costs. Colloidal fouling is particularly challenging because it may not be easily removed by standard cleaning procedures. At BLUFOX membranes, we recommend effective pretreatment and monitoring strategies to minimize the risks of colloidal fouling, ensuring smoother operation and longer membrane durability.

Can Bio-Fouling Be Prevented?

Bio-fouling occurs when microorganisms like bacteria, algae, and fungi grow on the membrane surface, forming a biological layer or biofilm. This type of fouling can be especially stubborn because once microbes start colonizing the membrane, they multiply rapidly and become difficult to remove, affecting water flow and system efficiency.

Preventing bio-fouling requires a proactive approach. This includes effective pretreatment of feed water, regular membrane cleaning, and in some cases, the use of disinfectants or anti-fouling coatings. At BLUFOX membranes, we focus on developing membranes that are more resistant to microbial growth, reducing the risk of bio-fouling and extending membrane life. Consistent maintenance and smart system design play key roles in minimizing the chances of bio-fouling in water and wastewater treatment systems.

Is Chemical Fouling a Common Issue in MBRs?

Yes, chemical fouling is a common issue in Membrane Bioreactors (MBRs), and it can significantly impact their performance. This type of fouling happens when chemical reactions between substances in the feed water and cleaning agents or additives result in the formation of insoluble compounds. These compounds then deposit on the membrane surface, leading to reduced permeability and higher operating pressures.

In MBR systems, chemical fouling is often caused by interactions involving metal ions, disinfectants like chlorine, or pH imbalances. Over time, these reactions can form hard-to-remove layers that degrade the membrane material. At BLUFOX membranes, we recommend careful monitoring of chemical dosing and feed water quality, along with the use of compatible cleaning agents, to minimize the risk of chemical fouling and keep MBR systems running efficiently.

Conclusion

Fouling impacts MBR system efficiency by reducing permeate flux, increasing energy use, and raising operational costs. Effective cleaning and maintenance strategies are key to minimizing these effects.

At BluFox Membranes, we offer fouling-resistant MBR membranes for optimal performance. Visit blufoxmembranes.com for more information.

Prevent fouling with BluFox Membranes to maximize system efficiency!

mbr membrane price

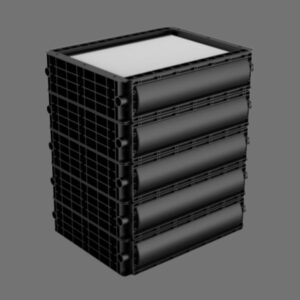

BF Series Hollow Fibre Membrane Modules

Hollow Fibre Membrane Modules (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

SUS Series Hollow Fibre Membrane Modules

Hollow Fiber MBR (membrane bioreactor) membranes are a type of membrane used in wastewater treatment systems to purify and remove impurities from wastewater.

Submerge Type Poreflon Module

POREFLON Membrane Modules are durable high – quality membranes that have a chemical and thermal resistance. These modules are reasonably priced and easy to handle.

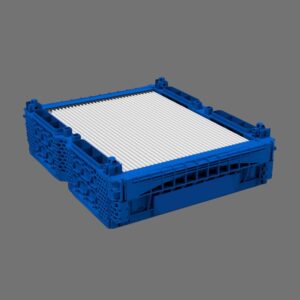

BF Flat Sheet Membrane

BF Flat sheet MBR membrane is a high – performance wastewater treatment membrane that uses a flat sheet design. This innovative design allows for more efficient cleaning and higher performance than traditional treating methods.

Ceramic Flat Sheet Membrane

The flat ceramic membrane is a new type of high-temperature plate porous ceramic membrane, which is prepared by a high – temperature sintering process using inorganic materials such as alumina.

UF Membrane

UF membrane technology has revolutionized the water treatment industry. The UF membrane removes impurities & contaminants from water at a molecular level, resulting in clean, safe, and purified water.

Applications

Membrane reactors are used throughout the world, for industrial as well as municipal wastewater.

For industrial wastewater, there are various full-scale applications in a variety of industrial sectors, such as foods, (petro) chemicals, pharmacy, electronics, laundries, paper, textile, agriculture, abattoirs, and percolate waters from disposal sites and hospitals.

Other sectors where MBR may be implemented include the Processing of finished oil, sludge from wastewater purification, car body repair and car body companies, car and truck wash, the graphics industry, tank and barrel cleaning, paint, glaze, varnish and printing ink production, foundries, metal processing, and refineries.

Why Choose Blufox?

We are a high-tech enterprise specializing in wastewater treatment industries. We have the core technology of producing MBR membrane components and have high production capacity, aiming to build a high-quality brand of MBR production and sales all over the world.

Factory Supply

Our factory has 2 production lines dedicated to the production of MBR Membrane.

Great support

The staff you interface with are experienced and certified in their English language skills.

Design on Demand

You provide the project information and we generally will give you a solution.

Quality Standards

We have a very professional quality audit process after the production is completed.

Happy Clients

I have been working with Blufox for 2 years now, and I am glad I chose them from the beginning. Their products are of very high quality, and my clients have never complained about their products. Besides MBR membranes, they also have other good quality products, such as water pumps and air blowers, which suit my projects well. So if possible, I suggest you try their other products as well.

Hollow Fibre Membrane

Hollow Fibre Membranes

Top 10 MBR Membrane Companies in India

Top 5 MBR Membrane Companies in India

Membrane Bioreactors

Chemical MBR Packaged Membrane System

Chemical MBR Packaged Membrane

Hollow Fibre Membrane Modules

Introduction

Membrane bioreactor (MBR) technology is a highly efficient and cost-effective way of treating wastewater. It combines the conventional activated sludge process with membrane filtration technology to remove contaminants and produce high-quality effluent. The MBR process has gained popularity in India due to its ability to produce high-quality treated water, minimize environmental impact, and reduce operational costs. In this article, we will discuss MBR membrane manufacturers in India and why blufoxmembranes.com is the best company for it.

Hollow Fibre Membrane Modules Manufacturers in India

There are several MBR membrane manufacturers in India. Some of the popular manufacturers include:

Blufox Eco Ventures

Dow Chemicals India Pvt Ltd

Hydranautics – A Nitto Group Company

Toray Industries (India) Pvt. Ltd.

Pall India Pvt Ltd

Membrane Solutions Pvt Ltd

Pentair Water India Pvt Ltd

Blufox Membranes – The Best Company for MBR Membrane

Among the many MBR membrane manufacturers in India, Blufox Membranes stands out as the best company. Blufox Membranes is a leading provider of MBR membranes in India. The company specializes in the design, manufacturing, and supply of advanced membrane solutions for wastewater treatment applications. Blufox Membranes has established itself as a market leader in MBR membrane technology due to its commitment to quality, reliability, and innovation. Hollow Fibre Membrane Modules

Blufox Membranes produces high-quality membranes that are designed to provide optimal performance and durability. The membranes are manufactured using state-of-the-art equipment and advanced materials to ensure that they meet the highest standards of quality. Blufox Membranes also offers a wide range of membrane products to meet the needs of different wastewater treatment applications. These products include ultrafiltration (UF) membranes, microfiltration (MF) membranes, and nanofiltration (NF) membranes. Hollow Fibre Membrane Modules

Blufox Membranes has a team of experienced and knowledgeable professionals who are dedicated to providing excellent customer service. The company’s technical support team is always available to help customers with any technical questions or issues that they may have. Blufox Membranes also provides training and support to its customers to help them maximize the performance of their membrane systems. Hollow Fibre Membrane Modules

In addition to producing high-quality membranes, Blufox Membranes also offers cost-effective solutions to its customers. The company’s membranes are designed to be long-lasting and require minimal maintenance, which helps to reduce operational costs. Blufox Membranes also offers competitive pricing on its products, which makes it an affordable option for many wastewater treatment applications.

Conclusion

MBR membrane technology is becoming increasingly popular in India due to its ability to produce high-quality treated water, minimize environmental impact, and reduce operational costs. There are several MBR membrane manufacturers in India, but Blufox Membranes stands out as the best company for MBR membrane technology. Blufox Membranes produces high-quality membranes that are designed to provide optimal performance and durability. The company also offers excellent customer service, cost-effective solutions, and competitive pricing, which makes it an ideal choice for wastewater treatment applications. If you are looking for an MBR membrane manufacturer in India, we highly recommend blufoxmembranes.com.

Introducing the extraordinary world of Hollow Fibre Membrane Modules, where innovation and efficiency converge to redefine the realm of filtration and separation processes. These remarkable modules are the epitome of cutting-edge technology, harnessing the power of hollow fibres to revolutionize various industries and applications.

Imagine a network of slender, microscopic tubes intricately woven together, forming a labyrinthine matrix within the core of a compact module. These hollow fibres, composed of high-performance materials such as polymers or ceramics, possess an intricate structure that combines remarkable strength with exceptional permeability.

The true marvel lies in the remarkable capabilities of these hollow fibres. Each individual fibre acts as a conduit, enabling precise control over the separation and filtration processes. Fluids, gases, or even suspended particles encounter the intricate web of fibres, undergoing a meticulous journey of purification and extraction.

Within this intricate framework, countless applications come to life. From water treatment and desalination to pharmaceutical and biotechnological processes, Hollow Fibre Membrane Modules find their place at the forefront of scientific advancement. They elegantly tackle challenges ranging from removing impurities and contaminants to facilitating the separation of valuable compounds, all while minimizing energy consumption and waste production.

Their versatility knows no bounds. These modules gracefully navigate the intricate dance of separating components based on size, molecular weight, or even charge, effectively enabling the extraction of vital substances and the elimination of unwanted elements. The result is an enhanced and sustainable production process, ensuring the highest quality and purity for a myriad of industries.

Beyond their exceptional performance, these modules boast unparalleled scalability and flexibility. As the demand for filtration and separation grows, Hollow Fibre Membrane Modules effortlessly adapt, seamlessly integrating into existing systems or spearheading the design of novel architectures. Their modular nature allows for easy customization, enabling tailored solutions that meet the unique requirements of each application.

However, their impact extends beyond industries and laboratories. Hollow Fibre Membrane Modules have the potential to revolutionize the lives of millions, providing access to clean water in remote regions or disaster-stricken areas. Their ability to efficiently remove harmful pathogens and contaminants offers a glimmer of hope for those in dire need, uplifting communities and transforming lives.

In the realm of innovation, Hollow Fibre Membrane Modules stand tall, embodying the pinnacle of technological achievement in the field of filtration and separation. Through their exceptional capabilities, they redefine what is possible, empowering industries, enabling progress, and creating a brighter, more sustainable future for all.